Transform thermal imaging data into predictive intelligence across industries.

Unlike traditional manual inspections, STYRA transforms raw thermal data into actionable intelligence instantly.

Thermal imaging data is collected from your existing hardware or drones.

Edge AI processes raw images instantly to identify thermal anomalies.

Receive predictive alerts & generate automated maintenance plans.

Raw thermal data → Actionable intelligence in 30 seconds

Data Input

AI Processing

Predictive Insight

Advanced Machine Learning built for industrial reliability.

STYRA isn't just another dashboard. It integrates natively into your existing operational workflows.

Why industry leaders are switching to AI-driven monitoring.

| Metric | Traditional Inspection | STYRA AI |

|---|---|---|

| Inspection Time | 8 hours | 30 minutes |

| False Positives | 25% | 2% |

| Downtime Reduction | 10% | 35% |

| Maintenance Costs | Baseline | -28% Savings |

| ROI Timeline | 18 months | 6 months |

Scale from a single asset to enterprise-wide monitoring.

Join organizations transforming reliability with STYRA.

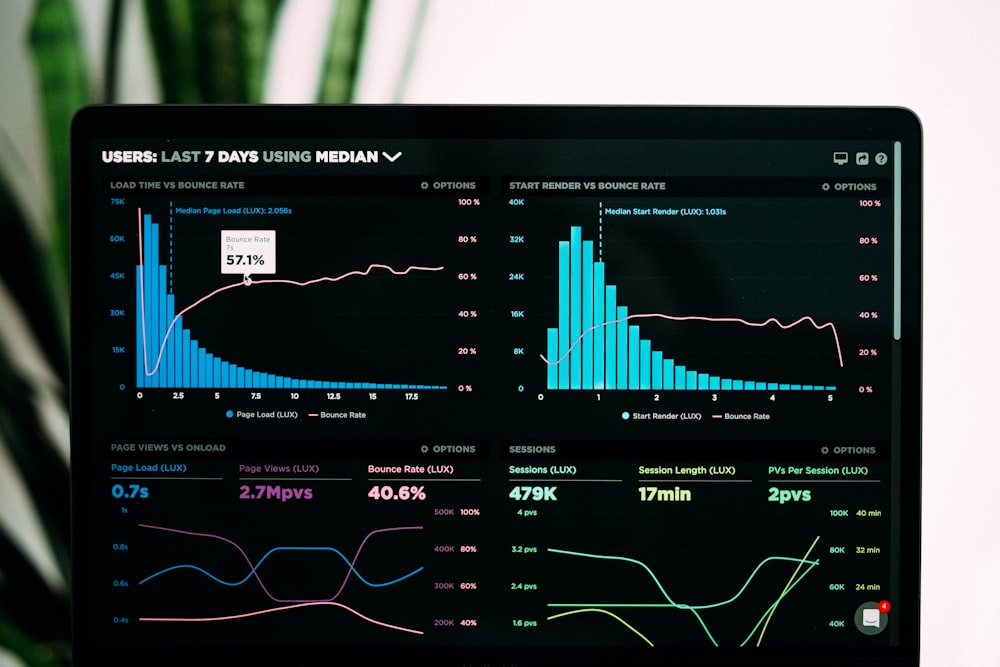

STYRA's highly configurable platform has transformed our substation condition monitoring. Seamlessly integrating with FLIR thermal and PD imagery, its AI-powered automated tagging eliminates manual efforts while ensuring error-free accuracy. The comprehensive dashboard provides executive-level visibility—substation health overview, survey progress, test results, equipment-wise health indices, interactive charts, rectification tracking, hierarchical drill-downs, and map-based location views. With multi-level filters and downloadable reports (test-wise, equipment-wise, voltage class, severity-based), decision-making is simplified across all levels. From predictive/preventive maintenance planning to optimized resource allocation, STYRA delivers unmatched asset intelligence.